Random Posts

3/random/post-list

Popular Posts

Electrical Cable/Wire Sizing

October 15, 2019

Contact form

MOTOR USING Greasing Materials- EP2 Grease

Dhruvang Suthar

October 20, 2019

What is EP2 Grease?

“Lubricant greases are semisolid products that have high initial viscosity commonly applied in wheel bearings and constant velocity joints. They are made from emulsified soap with oil and provide parts with what is called “thixotropy”. Thixotropy is defined as the shear-thinning property of “flowing” usually thick or viscous fluids through stress.“

In vehicle applications, EP2 greases are applied on parts that cannot be frequently lubricated. It is also used on parts where lubricating oil usually doesn’t stay in position. In addition to this, EP2 grease can also act as a sealant that prevents ingress of incompressible components and water.

EP2 Grease. What does it stand for?

One type of lubricant grease used in automobiles is EP2 lithium grease. What is it ? It is a general purpose lithium-soap thickened grease for extreme pressures. Here, soaps disperse and viscosify oil to create the stable gels of greases. Lithium greases are non-corrosive and adhere very well to metal. They are also particularly great with heavy loads and have good temperature tolerances.

The said, properties are what makes EP2 grease popular for household products and automotive parts (e.g. CV joints, u-joints, ball joints, etc.) usage. Some formulations of this grease type include other substances like PTFE and molybdenum disulfide.

The presence of a lithium thickener in this type of grease increases operating stability range. Lithium’s good capability of coping stresses, also makes this grease type outstanding in managing a shift from low to high temperature.

EP2 Grease – What is it and its Applications?

EP2 Grease – What is it and its Applications?

EP2 lithium grease is best used for applications that involve a wide range of temperatures and high/extreme pressure conditions. This type has a higher melting point (around 500°F or 260°C or more) as compared to conventional lithium greases. This quality makes perfect for applications that involves heavier stresses and loads.

This type of grease also aids demanding applications by preventing leakage and meltdown. These properties make it great for high stress applications common in trucks. It is also great for the wheel bearings of conventional and disc brakes where conventional grease can and will usually melt. Below are other common applications where EP2 lithium grease can be used:

- Disc brakes

- Wheel bearings

- Chassis

- U-Joints

- Ball Joints

Why is EP2 Grease Popular?

Why is EP2 Grease Popular?

EP2 grease is very popular for its versatility. The flexibility of its thickeners can be applied to a broad range of applications. In fact, despite it being more expensive, it is more advisable to use than other types of greases because it offers more advantages and has more uses. When choosing an EP2 grease, it is a must to consider an application’s operating temperature.

EP2 grease lubricants, moreover, also have better mechanical stability or shear stability than other grease types. It has good resistance against shear and breakdown because of its ability to remain its designed consistency and thickness (or viscosity) even when exposed to high mechanical shear forces.

There are basically two types of lithium greases one can choose from. The first are lithium complex greases and the second are simple lithium soap greases. The former are commonly used for general lubricating purposes while the latter are for more specific uses.

Generally, however, lithium complex greases are considered better choices because they have better dropping points, mechanical stability, water resistance, and oil separation resistance.

What is Lithium Complex in EP2 grease?

Lithium complex greases were first developed in the 1940’s with the patent granted to Lester W. McClennan. It was only until the 1980s, however, when this grease type was finally released to the market. Since then, it has slowly replaced simple lithium complex greases which had been the choice product at the time.

Lithium complex greases have a higher dropping point (read below to find out more about this) as compared to the simple soap ones. This is because it has a second thickener component or complexing agent. EP2 grease variants nowadays also employ a shorter chain-length difunctional carboxylic acid. Moreover, modern lithium complex greases contain lower lithium salt content now as well.

Dropping Point of EP2 Grease

The dropping point of a lubricating grease refers to the temperature at which its semi-solid state turns into a liquid under test conditions. This figure is usually provided following the ASTM standard products, the higher the figure, the better because it means it can survive higher stressed conditions. For best results, look for a product with a dropping point of F. 650+.

Water Washout in EP2 Grease

Water washout is the term used to refer to the solubility of the thickener in the product. A good example of a thickener is lithium hydroxide which only has about 10 percent solubility. The lower the solubility of a thickener, the better, because it means it has better resistance against water washing and absorption.

Other lithium thickener types like barium and calcium have better water washout capacities. However, certain negative aspects in their flexibility to applications makes them less than desirable. The water resistance of a lithium EP2 grease can be improved by adding polymer additives to it in small concentrations.

Pumpability in Lubrication Greases

The pumpability of a grease refers to its ability to be pushed or pumped in a system. A pressurized lubrication grease should be easily pumped through nozzles, lines, and fittings of grease-dispensing systems. Pumpability can be related to ‘apparent viscosity’ which is identified by measuring the flow rate of pressurized grease within long pipes.

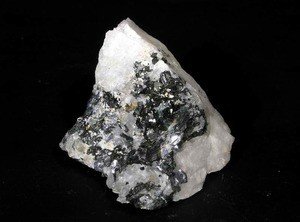

Molybdenum disulfide in EP2 Grease

Molybdenum disulfide in EP2 Grease

Molybdenum disulfide is a popular lubricant which was first used in military and aerospace applications. At present, it is now used in various lubrication greases for automotive and industrial use. This compound is very helpful in providing boundary lubrication to metal parts in contact with each other. Molybdenum disulfide provides better lubrication functions than the hydrodynamic regime where a thick fluid film is applied between parts. A high percentage (e.g. 10%) of this compound in a lubricant provides better results because they reach deeper valleys in parts, offer a smoother finish, and better load-carrying ability.

NLGI Consistency Number/Grade

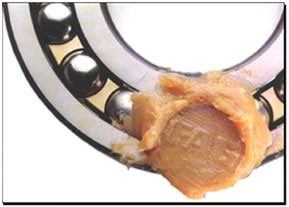

The NLGI consistency/grade is a unit of measure of the relative hardness of a lubrication grease. NLGI grade is divided into 9 categories with the numbers starting from 000 to 9. The 000 grade has a fluid consistency while NLGI 2 has the consistency of peanut butter. It is also the one considered as the “normal grease”. Grade 6, which is the hardest has the hardness similar to cheddar cheese.

Rust Prevention in Lubrication Grease

Greases are not allowed to be corrosive to metals or exhibit corrosive qualities such as oxidation and aging. The rust prevention or resistance of a grease is determined by the ASTM D 1743 Test Method for Corrosion Preventive Properties of Lubricating Greases. A lithium that has passed this test means that it is capable of preventing corrosion and rusting in both storage and static conditions. An EP2 grease with a relatively good service condition under static conditions, moreover, is considered excellent.

4 Ball Wear Test on EP2 Grease

4 Ball Wear Test on EP2 Grease

The 4 ball wear test is a method that determines the capability of greases to prevent wear between steel-on-steel applications. Related to this is the 4 ball EP tester which is commonly used to test heavier loads under severe conditions.

The weld point in a 4 ball EP test refers to the load at which the lubricant finally breaks down. It also refers to the temperature at the point of contact in which a metal finally melts. A good figure in an EP2 grease is around 700 and more because it means the lubricant has a higher resistance against meltdown and breaking. Connected to this is the scar diameter which refers to the size of scarring on parts the moment they break. A low scar diameter (millimeters only) is a good figure.

Load Wear Index in Lubrication Greases

The load wear index in greases is calculated from the scar diameter figure. It is a method used to determine the temperature (low, medium, high) of extreme pressures that can be handled by greases. A high load wear index in an EP2 grease determines superior performance against wearing and extreme pressure.

Mobilux™ EP Series

Mobil Grease, United States

Product Description

Mobilux™ EP 0, 1, 2, 3, 004 and 023 products are a high performance family of four general-purpose industrial greases and two special-duty semi-fluid greases. These lithium hydroxystearate greases are formulated to provide extra protection against wear, rusting and water washout. They are available in NLGI grades ranging from 00 to 3, with base oil viscosities ISO VG 150 and 320.

Mobilux EP 0, 1, 2 and 3 greases are recommended for most types of industrial applications including heavy-duty applications where high unit pressures or shock loads are present. These greases provide excellent protection against rust and corrosion and resist water wash-out which makes them particularly suitable for equipment where moist or wet conditions are common. Mobilux EP 0 and 1 are suitable for centralised systems. Mobilux EP 2 and 3 are general-purpose greases. The recommended operating temperature range is from -20ºC to 130ºC but they may be used at higher temperatures if the lubrication frequency is increased accordingly.

Mobilux EP 004 and Mobilux EP 023 are particularly suitable for the lubrication of enclosed gears and bearings in poorly sealed gear cases they can also be used in many other industrial applications where conventional gear oils cannot be retained in gear cases, chain cases, etc. because of leakage due to worn or missing seals. The recommended operating temperature range is -20 to 120ºC for Mobilux EP 004 and -20 to 120ºC for Mobilux EP 023.

Features and Benefits

Mobilux EP greases have a long history of proven performance and have demonstrated good performance in the areas of corrosion protection, low temperature pumpability and high temperature service life. A Timken OK load of 40 lb illustrates their load carrying and extreme pressure capability.

• Reduced wear under heavy or shock loading and vibration for good equipment reliability and availability

• Protection against rust and corrosion and resistance to water washout for equipment protection and good lubrication even in presence of water

• Extended bearing life potential in wet environments for reduced bearing costs and unanticipated downtime

• Good pumpability in centralised systems (Mobilux EP 0 and 1)

• Effective leakage control (Mobilux EP 004 and Mobilux EP 023)

Applications

• Mobilux EP 0 and EP 1 provide good low temperature pumpability and are suitable for centralised lubrication systems and other applications where low temperature performance is required.

• Mobilux EP 2 is recommended for multipurpose applications in antifriction and plain bearings, bushings and pins under normal operating conditions.

• Mobilux EP 3 is a stiffer NLGI grade 3 grease recommended for applications where maximum protection against penetration of water or solid contaminants is required.

• Mobilux EP 004 and Mobilux EP 023 are particularly suitable for the lubrication of enclosed gears and bearings in poorly sealed gear cases on most underground mining machinery with the exception of electric motor gearings. Mobilux EP 004 and Mobilux EP 023 can also be used in many other industrial applications where conventional gear oils cannot be retained in equipment such as gear cases, chain cases, because of leakage due to worn or missing seals. Mobilux EP 004 passes the SEW 1008 hour gear test requirement DR.EM.203 mod.

Specifications and Approvals

This product has the following approvals:

|

MOBILUX EP 0

|

MOBILUX EP 1

|

MOBILUX EP 2

|

MOBILUX EP 3

|

MOBILUX EP 004

|

MOBILUX EP 023

|

SEW-Eurodrive PS C Gears

|

|

|

|

|

X

|

|

This product meets or exceeds the requirements of:

|

|

|

|

|

|

|

DIN 51825:2004-06 - KP 1 K -20

|

|

X

|

|

|

|

|

DIN 51825:2004-06 - KP 2 K -20

|

|

|

X

|

|

|

|

DIN 51825:2004-06 - KP 3 K -20

|

|

|

|

X

|

|

|

DIN 51826:2005-01 - GP 000 G -20

|

|

|

|

|

|

X

|

DIN 51826:2005-01 - GP 00 G -20

|

|

|

|

|

X

|

|

DIN 51826:2005-01 - GP 0 G -20

|

X

|

|

|

|

|

|

Properties and Specifications

Property

|

MOBILUX EP 0

|

MOBILUX EP 1

|

MOBILUX EP 2

|

MOBILUX EP 3

|

MOBILUX EP 004

|

MOBILUX EP 023

|

Grade

|

NLGI 0

|

NLGI 1

|

NLGI 2

|

NLGI 3

|

NLGI 00

|

NLGI 000

|

Thickener Type

|

Lithium

|

Lithium

|

Lithium

|

Lithium

|

Lithium

|

Lithium

|

Base Oil Viscosity of Greases @ 40 C, mm2/s, AMS 1697

|

160

|

160

|

160

|

160

|

160

|

320

|

Color, Visual

|

BROWN

|

BROWN

|

BROWN

|

BROWN

|

BROWN

|

BROWN

|

Dropping Point, °C, ASTM D2265

|

190

|

190

|

190

|

190

|

0

|

0

|

Four-Ball Extreme Pressure Test, Weld Load, kgf, ASTM D2596

|

250

|

|

|

|

250

|

|

Four-Ball Extreme Pressure Test, Weld Point, kgf, ASTM D2596

|

|

250

|

250

|

250

|

|

250

|

Four-Ball Wear Test, Scar Diameter, mm, ASTM D2266

|

0.4

|

0.4

|

0.4

|

0.4

|

|

0.4

|

Four-Ball Wear Test, Scar Diameter, 40 kg, 1200 rpm, 1 h, 75 C, mm, ASTM D2266

|

|

|

|

|

0.5

|

|

Penetration, 60X, 0.1 mm, ASTM D217

|

370

|

325

|

280

|

235

|

415

|

460

|

SKF Emcor Rust Test, Distilled Water, ASTM D6138

|

|

|

|

|

0-0

|

0-0

|

SKF Emcor Rust Test, Distilled Water, Bearing 1, ASTM D6138

|

0

|

0

|

0

|

0

|

|

|

SKF Emcor Rust Test, Distilled Water, Bearing 2, ASTM D6138

|

0

|

0

|

0

|

0

|

|

|

Timken OK Load, kg, ASTM D2509

|

40

|

40

|

40

|

40

|

40

|

40

|

Health and Safety

Health and Safety recommendations for this product can be found on the Material Safety Data Sheet (MSDS) @ http://www.msds.exxonmobil.com/psims/psims.aspx

All trademarks used herein are trademarks or registered trademarks of Exxon Mobil Corporation or one of its subsidiaries unless indicated otherwise.

08-2019You may like these posts

Certificate of Completion

Certificate No.CERT001561786-EMI

Total Pageviews

This Page is a little effort to make you Sharing of some own materials .This is just a Kick-Start to make the aware of Practical World !!! Best of luck.-DHRUVANG SUTHAR

Created By SoraTemplates | Distributed By Gooyaabi Templates

1 Comments

If you are looking for best heavy equipment grease then look no further than Petron Plus Direct! Our products have been carefully and extensively field-tested.

ReplyDelete